Complexity:

Modeling approach: discrete-event

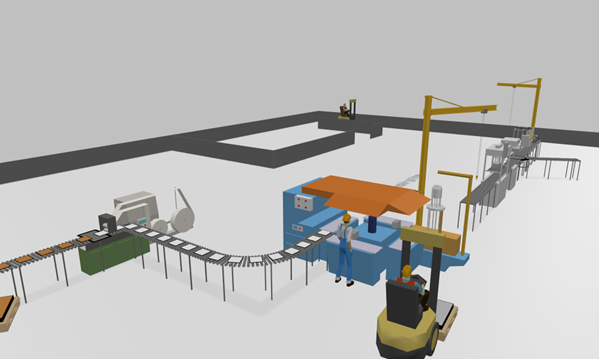

Features: Material Handling Library Process Modeling Library conveyor transporter 3D custom flowchart block

This tutorial will teach AnyLogic users to create material handling models with the help of the Material Handling Library and Process Modeling Library. We will show you how to model a lead acid batteries production line utilizing conveyors, industrial cranes, and AGVs that move both along guiding lines or in free space.

- Phase 1. Pasting of the electrodes and collecting them into batches.

- Phase 2. Transferring the batches to the drying chambers by the forklifts moving in free space.

- Phase 3. Wrapping of electrodes in the special envelopes and assembling electrode groups.

- Phase 4. Assembling the battery by placing the electrode groups inside the case with the help of an industrial crane.

- Phase 5. Adding caps and terminals to the battery, checking the battery for leakage, and filling the battery with electrolyte.

- Phase 6. Delivering the batteries to the charging location by the path-guided forklifts.

- Phase 7. Creating a custom block to diversify the manufacturing process for anodes and cathodes.

- Phase 8. Modeling the process of electrode production from sheets of metal with the help of the Fluid Library.

Start the tutorial by following the link below to the document describing the first phase.

-

How can we improve this article?

-